柴油发电机组日常维护保养

柴油发电机组保养周期规定:每月两次,并作好保养记录

柴油发电机组保养部位:空滤、气滤、蓄电池、控制面板、机油、防冻液。

1、蓄电池维护

蓄电池电线夹头与电瓶连接桩柱应保持清洁。用毛刷小心清理电瓶接线桩柱与电线夹上的尘污和氧化物,电线端夹应拧紧并涂上润滑脂,在外加凡士林以防少十与氧化而导致漏电或放电。电解液应保持一定高度,以免极板的损坏。电解液液位应超过电瓶格栅板大约10mm(免维护电池除外)。应定期检查电解液比重,电解液比重为128G/cm³,当电解液比重下降至124G/CM时,应立即充电(免维护电池除外)。

2、更换润滑油

更换润滑油应在停机状态进行,用泵或拆下油槽放油塞排出润滑油,放出的润滑油应用容器收集起来。注入新油,使润滑油达到量游标记至高位线,起动发动机运转5-10秒钟停机,停置15分钟,检查润滑油油位,注油使其达到H点。

3、空气滤清气的更换和清洁

拆下空气滤清器纸滤芯,用低压压缩空气清理芯子,清理时空气皮管由滤芯向外吹,以清除尘土,压缩器内不允许含有油污和水。清理后检查滤芯,确保没有洞眼。有洞眼或被堵塞的滤芯必须更换,否则会加速发动机磨损或功率下降。用干净布把壳体擦干净,检查橡胶密封垫圈,更换失效或以损坏的橡胶圈。装上新的或清理过的滤芯。按下调节按钮,使警告指示器重拨至零位。

4、空气冷却器清洁

如果空气冷却器污染物较多,影响通风效果,则去除风扇罩,松开冷却器连接管,从水箱中松开冷却器,用水小心冲洗。注意:为了仿止散热片不受损坏,请勿使用高压水清洗。

注:

1、如果燃气机停用超过14天,则每14天要启动一次,到暖机为止;

2、润滑油油位检查,发动机量油尺上有两个标记,高位/低位,油位应在标记范围内,切记不能低于最低线;

3、冷却液的检查,冷却液加至低于加水口盖4-5mm左右,留有冷却液受热膨胀的空间:为保证防腐蚀保护效果,发动机每运行400小时,再加入1/2升防腐蚀的冷却液;

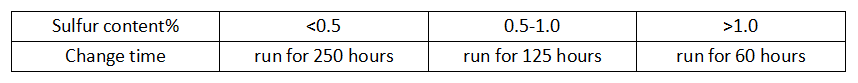

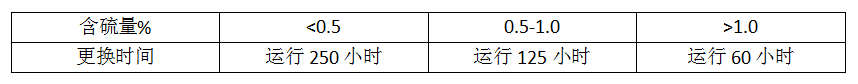

4、润滑油在发动机运行累计时间达到更换周期时,应更换为:

Daily maintenance and upkeep of diesel generator sets

The maintenance cycle for diesel generator sets is stipulated as twice a month, and maintenance records should be kept

Maintenance parts of diesel generator set: air filter, air filter, battery, control panel, engine oil, antifreeze.

1. Battery maintenance

The battery wire clamp and battery connection post should be kept clean. Carefully clean the dust and oxides on the battery terminal post and wire clamp with a brush. The wire end clamp should be tightened and coated with lubricating grease, and Vaseline should be added to prevent leakage or discharge caused by oxidation. The electrolyte should be kept at a certain height to prevent damage to the electrode plates. The electrolyte level should exceed the battery grid plate by approximately 10mm (excluding maintenance free batteries). The electrolyte density should be checked regularly. The electrolyte density is 128G/cm ³. When the electrolyte density drops to 124G/CM, it should be charged immediately (except for maintenance free batteries).

2. Replace lubricating oil

The replacement of lubricating oil should be carried out when the machine is stopped. Use a pump or remove the oil drain plug from the oil tank to discharge the lubricating oil, and collect the discharged lubricating oil in a container. Inject new oil until the lubricating oil reaches the high level mark, start the engine and run for 5-10 seconds, stop for 15 minutes, check the lubricating oil level, and inject oil until it reaches the H point.

3. Replacement and cleaning of air filters

Remove the paper filter element of the air filter, clean the element with low-pressure compressed air, and blow the air hose outward from the filter element during cleaning to remove dust. The compressor is not allowed to contain oil and water. After cleaning, check the filter element to ensure there are no holes. Filter elements with holes or blockages must be replaced, otherwise it will accelerate engine wear or power loss. Clean the shell with a clean cloth, inspect the rubber sealing gasket, and replace any faulty or damaged rubber rings. Install a new or cleaned filter element. Press the adjustment button to reset the warning indicator to zero.

4. Air cooler cleaning

If there are many pollutants in the air cooler that affect the ventilation effect, remove the fan cover, loosen the cooler connection pipe, release the cooler from the water tank, and carefully rinse with water. Attention: To prevent damage to the heat sink, do not use high-pressure water for cleaning.

Note:

1. If the gas turbine is stopped for more than 14 days, it should be started every 14 days until it is warmed up;

2. Lubricating oil level check: There are two markings on the engine dipstick, high/low, and the oil level should be within the marked range. Remember not to lower it below the lowest line;

3. Check the coolant, add the coolant to a level about 4-5mm below the water inlet cover, leaving space for the coolant to expand when heated. To ensure anti-corrosion protection, add 1/2 liter of anti-corrosion coolant every 400 hours of engine operation;

4. When the accumulated running time of the engine reaches the replacement cycle, the lubricating oil should be replaced with: